B. Braun supplied with Suncombe’s IBC WashBooth units

The Client

Founded in 1839 in Melsungen, Germany, B. Braun is an expert and veteran Medical and Pharmaceutical device company. With facilities and offices in more than 50 countries, B. Braun paves the way in medical technology.

In 2016, B. Braun commissioned a production plant in Rubi, Spain, an 80 million euros investment with over 3,000 employees, which deals with the production of serums and other intravenously applied medical solutions. In addition, the production plant is used to manufacture containers and bottles fit for pharmaceutical use.

Rubi, Barcelona, Spain B. Braun Production Plant

The Rationale

The Rubi production plant deals with the production of serums and other intravenously applied medical solutions. In addition, the production plant is used to manufacture containers and bottles fit for pharmaceutical use, these production purposes combined led B. Braun to invest in a IBC Bin washer system for the cleaning of their containers and products.

The Project

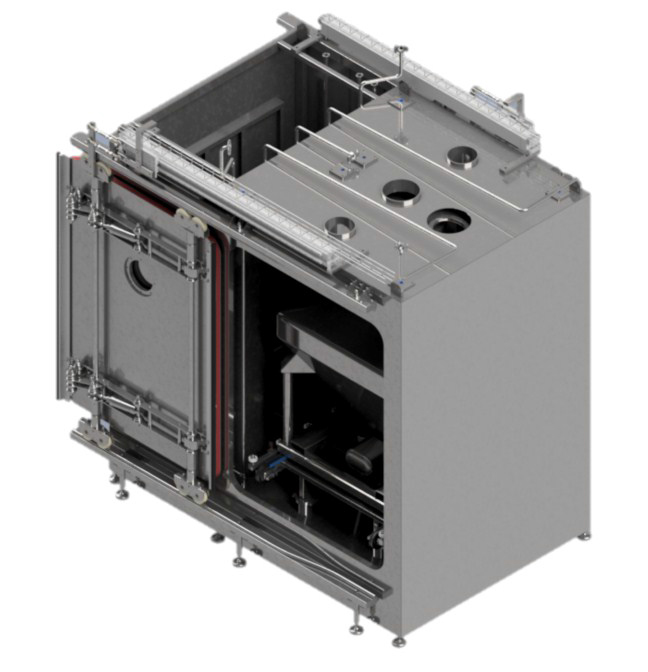

Suncombe was proud to work alongside B. Braun in supplying Suncombe’s IBC WashBooth units, for the purpose of cleaning and drying 700L IBCs/BINs at the Rubi plant. The design and capabilities of the WashBooth were developed to suit B. Braun’s requirements, this lead Suncombe to develop an innovative fully automated WashBooth.

Washbooth

Washbooth

The design featured automatic loading and unloading of the IBC/BIN through the use of a conveyor belt, automatic dis-mantling of the containers, allowing for internal and external cleaning, rinsing and drying. Automatic bin lid removal was employed in order to place a spray ball inside the container for thorough internal cleaning . The system was also equipped with a pneumatic split butterfly valve, designed to open and close the bottom valve for efficient draining of the CIP process.

Washbooth 3D Model

Benefits

The addition of the Suncombe WashBooth to the B. Braun, Rubi production plant allows the IBC/BIN to be cleaned efficiently and safely, with less manual handling and exposure to harmful substances for operators. The full automation of the Washbooth reduces labour costs as loading/unloading, and opening & closing of the BINs is carried out by mechanical instruments. This design also allows optimisation of the cleaning process, an automated system allows the input of multiple recipes for cleaning of various liquids, powders, and granulates.

Figure 4-Suncombe Ltd Washbooth, open door

Washbooth, open door

Washbooth, open door

Suncombe Comments

Keith Foskett, the lead design engineer at Suncombe, commented “Although the design and build of this booth was challenging, it was a wonderful opportunity to develop a standard product to suit our clients requirements. The standalone automation of the Booth proved to be a tough but great experience, I am proud to have represented Suncombe and worked side by side with B. Braun on this project.”

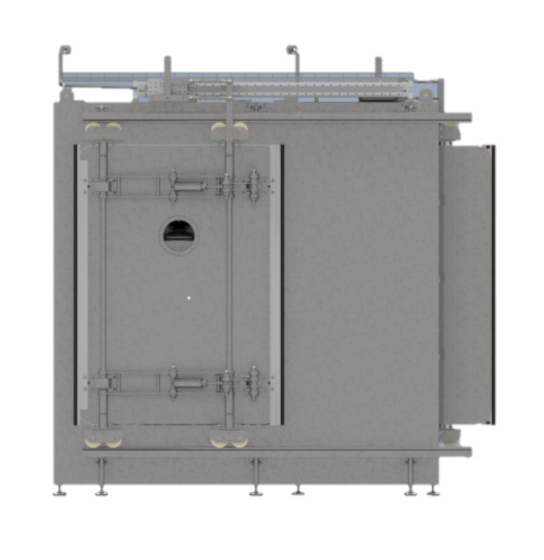

Figure 5-Suncombe Ltd Washbooth, front view 3D model.

Washbooth front view 3D model

Washbooth front view 3D model