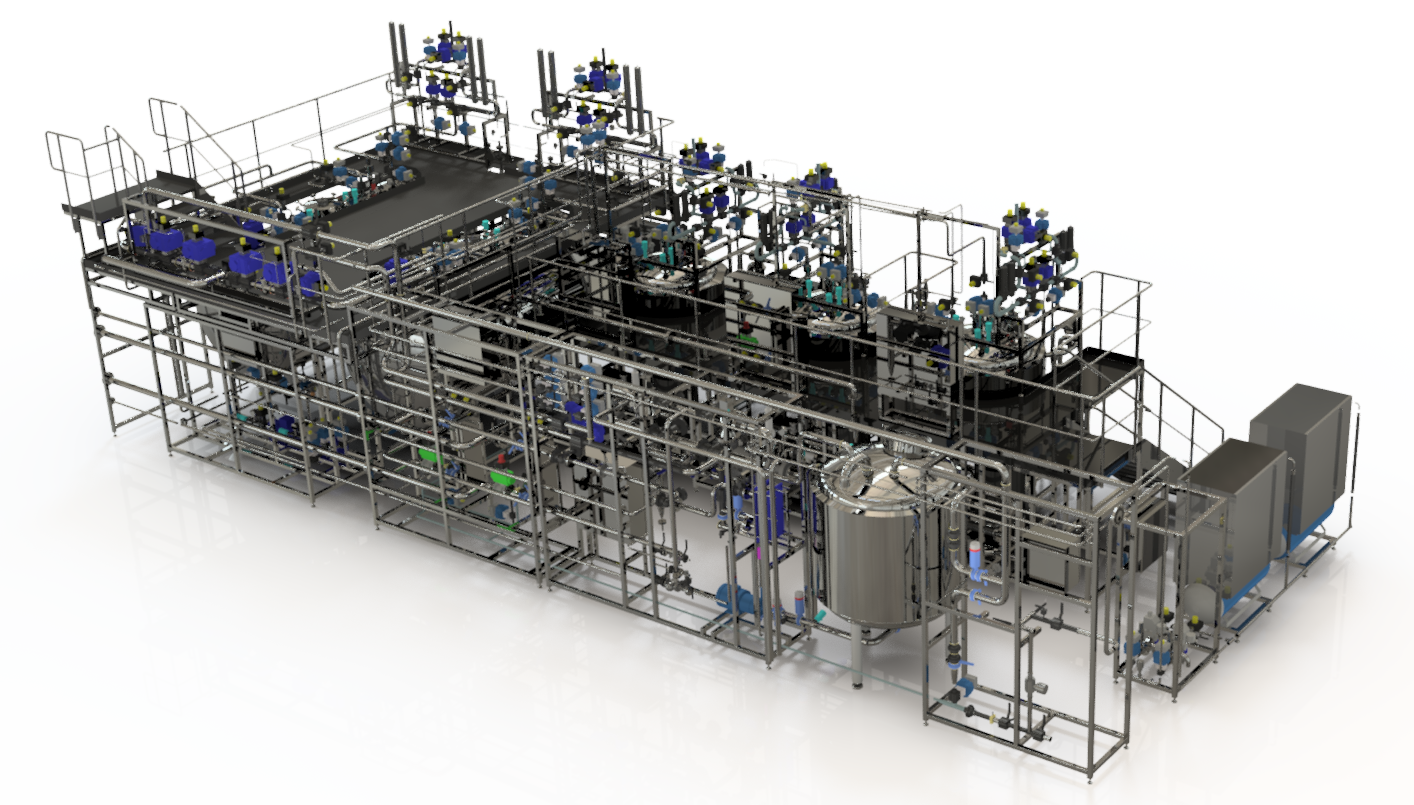

GMP Process Skids & Systems

Introduction to GMP Process Skids, Systems and Turnkey Schemes

- USP Water Storage Skids

- Solution Preparation

- Buffer and Media Preparation

- IBC Discharge Stations

- Final Formulation & Fill

- Powder Incorporation

- Process Utility Skids

- Filter Skids

- High Temperature Short Time (HTST) Skid

- Mixing Skids

- Pressurised Metered-Dose Inhaler (pMDI) Systems

- Blending

- Dilution

- Batching & Formulation

- Pasteurisation

- Super Skids

- Containerised Systems

- Spares life time support

- Design and project management for the future

Advantages of Processing Skids & Modules

• Smart Project Management controlling all aspects of the Skid/Module with a single Project Manager/Director.

• All aspects of the project carried out with in house staff including design, development, drawings, calculations, fabrication, finishing, piping, wiring, testing, automation, integration and testing.

• Skid/Module can be built and completed in parallel with the facility build of pre-built ready for a shutdown/changeover period.

• Pre-validated system allows full documentation and testing protocols to be performed prior to shipment.

Construction of Processing skids & modules

• Stainless steel, duplex and Hastelloy materials

• cGMP / FDA / ASME BPE / EHEDG

• Crevice free, certified surface finishes

• Full documentation and traceability

• Validation Protocols

• Pressure Equipment Directive (PED)

• Non-destructive testing

Speak to a skids specialist

Standardised Models

| Part # | Tank Volume Litres | Flowrate Litres per minutes | Head Pressure barg | Dimensions A (mm) | Dimensions B (mm) | Dimensions C (mm) |

|---|---|---|---|---|---|---|

| MobileCIP™60 – 1 Tank | 150 | 60 | 4.5 | 1,750 | 850 | 1,900 |

| MobileCIP™60 – 2 Tank | 2 x 150 | 60 | 4.5 | 1,750 | 850 | 2,350 |

| MobileCIP™60 – 2 Tank – Square | 2 x 150 | 60 | 4.5 | 1,750 | 1,400 | 1,400 |

| MobileCIP™100 – 1 Tank | + | ++ | + | 0 | + | 0 |

| MobileCIP™100 – 2 Tank | + | ++ | + | 0 | + | 0 |

| MobileCIP™150 – 1 Tank | + | ++ | 1,950 | 1,050 | 2,250 | |

| MobileCIP™150 – 2 Tank | 2 x 350 | 150 | 4.5 | 1,950 | 1,050 | 2,850 |

Key Features

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Custom specification product

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. To quickly generate an enquiry with us fill in the below form with as much detail as available to you, the form will auto-submit with your initial enquiry. This will enable our experts to begin assessing your system requirements and a sales representative to open a clear and concise channel of communication with you.

ASME BPE standard Pipework, fully annealed, chemistry to ASTM A-269, manufactured to ASTM A-270, and 3A Standard.

316 Stainless steel product contact parts, 304 non-contact parts, Hastelloy and Duplex Stainless.

T.I.G Welding; using argon gas purge, using a computer controlled enclosed head orbital welding plant.

PED Vessels, Complete material traceability, PD5500 compliant.

European Hygienic Engineering and Design Group (EHEDG)

Cost Matrices

Client Badging

GAMP

CE Compliant

Full Document Indexing

Working to ISPE

Industry 4.0 Ready

Data Manuals

3D Modelling

Corporate member of EBSA

Business Practices

- Cost Matrices

- Client Badging

- GAMP

- CE compliant

- Full Document Indexing

- Working to ISPE

- Industry 4.0 aware

- Complete Digital and/or physical Data Manuals

- 3D Modelling

- Corporate member of EBSA

Welding Standards

- BS EN 10204 – 3.1

- BS EN ISO 9606-1:2013

- BS EN ISO 15614-1:2004+A2:2012

Welding Standards

- BS EN 10204 – 3.1

- BS EN ISO 9606-1:2013

- BS EN ISO 15614-1:2004+A2:2012