About Us

EXPERIENCE AND RESOURCES

Since our foundation in 1961 by Dave Overton Sr. Suncombe has pioneered the development of innovative solutions for cleaning in place and bio-waste decontamination. The business continues to be privately owned by the Overton family and managed day to day by Dave and Steve Overton, sons of the founder. Supporting Dave and Steve is a closeknit, dedicated, highly motivated and long standing team encompassing a wealth of technical experience and knowledge in all relevant disciplines, including design, manufacture, automation, testing, installation, validation, documentation and after-sales support. The team employs the very latest techniques, standards and best in class solutions. Having such a strong team allows us to carry out almost all of our work in-house, under our direct control and quality management system. It also ensures that we own and preserve all the knowledge and experience gained with every project and allows us to offer continued support for all our installed systems throughout their lifetime.

All of our work is carried out across our own facilities, just off the M25 in North London in the United Kingdom. In addition to our internal resources we use a long-standing and proven supply chain for critical components and certain specialised sub-contracted operations. Our policy is to use market leading branded components where quality and safety are prioritised over cost.

SUNCOMBE SUMMARY

- We were formed over 50 years ago and have developed many innovative cleaning, hygienic and sterile processes.

- We are specialists in hygienic and sterile mechanical, welding and process engineering and automation.

- We supply standard and custom built Cleaning, Washing and Processing equipment.

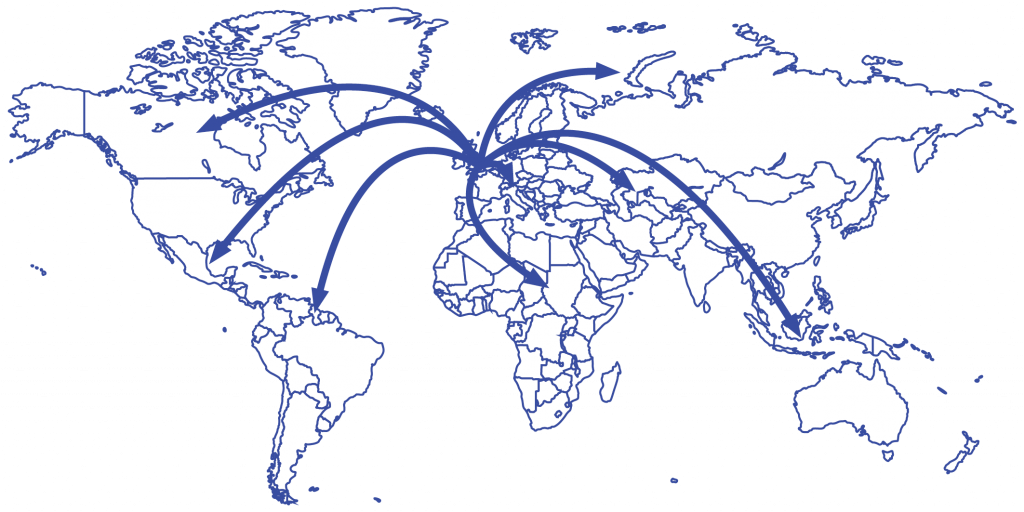

- We supply our equipment worldwide through a network of sales and service agents.

- All of our equipment is manufactured in the United Kingdom.

- We design and Manufacture to CE, cGMP, ASME BPE, EHEDG, GAMP, ATEX.

- We have In-house personnel for all disciplines.

- We have a motivated, dedicated and experienced long term employed team.

- Single point of contact for all aspects of a Project.

- Suncombe is a company focused on Cleaning In Place, BioWaste Treatment, GMP Washers and Sanitary Processing Equipment for the pharmaceutical, biotech and other critical industries.

- Suncombe has over 60 years of experience in the design, installation, validation, and operation of our high-quality systems.

- Suncombe has extensive in-house capabilities, allowing us to take full responsibility for all aspects of our projects with a single point contact.

- Designed and manufactured for reliability, repeatability and longevity, using a combination of traditional established and innovative design and manufacturing technologies, we have many systems that are 20, 30 and 40 years old, still in operation around the world.

- Our highly experienced and qualified personnel work with our clients from the initial idea phase, though conceptual design and the detailed design, encompassing: development, calculations, drawings, modelling, specification, fabrication, programming, documentation, factory acceptance testing, installation, commissioning, validation, project management and after sale services to the highest level of international standards.

- Suncombe systems are renowned for their expert design, superb reliability, low energy usage, low maintenance whilst complying with the highest regulatory standards.

- We work with the end users, engineering consultants and original equipment manufacturers.

- Many of the current recognised standard methodologies having been developed by Suncombe engineers over the last 60 years.

- Suncombe offer a complete package, from the initial idea phase, though conceptual design and the detailed design all backed by our 60 years as an independent company and with all of the required in depth technical knowledge and support, to guarantee the success of your project.

- Suncombe supply 17 out of the top 20 largest pharmaceutical and biotech companies in the world.

- Our Integrated Approach – when specifying critical equipment, you need to ensure that your partner has the in-depth technical knowledge to consider different solutions and methodologies and their product range is versatile enough to be customised to optimise the eventual solution.

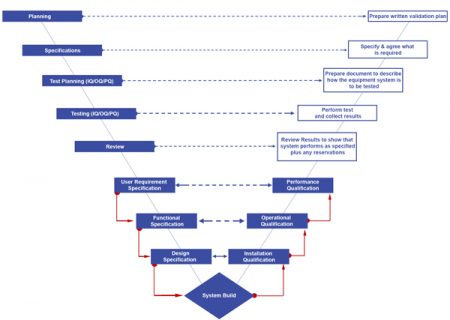

- Every Suncombe project is delivered by a nominated project team, who follow the V-model systems development lifecycle, to ensure that every solution meets your initial requirements. This approach allows us to customise our products to ensure they are reliable, repeatable and validateable.

MESSAGE FROM THE CHAIRMAN

Our company was created over 60 years ago specifically to supply a high quality range of process cleaning and sanitary processing equipment. To continually achieve our goals, we use the most up-to-date facilities and employ the best-qualified and experienced staff.

Our Manufacturing

Our Manufacturing

Our Facilities

Our Facilities

Our Values

Our Values

We are passionate about our business and our products

We offer Engineering Excellence and Value for Money

We pride ourselves on Innovative Design

We offer Quality in everything that we do and use robust

Health and Safety guidelines

Our Design

Our Design

Diagrams in ACAD

3D Modelling: Autodesk Inventor 3D Modelling is employed

throughout the design process

Timeline

The Company founder, Mr David Overton, worked in the development of a ground breaking new technology called Cleaning In Place in the 1950’s. This technology allowed production machinery to be cleaned without dis-mantling and proved to be a revolution for the pharmaceutical, food, dairy and beverage sectors, with great Health and Safety benefits and providing great savings in time, money and resources. The technology ensures a more reliable, robust procedure for cleaning and a guaranteed quality product.

In 1961 he started our company, Suncombe Ltd to further develop the technology of Cleaning In Place. Introducing Cleaning In Place to many new companies, it was found that the design of the processing equipment was not always suitable for this Cleaning In Place Process.

Subsequently, Mr Overton amalgamated a Process company called DA Engineering into the Suncombe organisation, to develop processing equipment, including Sanitary Tanks and Pressure Vessels, that could be Cleaned In Place.

Over the next decades the company, continued to develop Cleaning In Place and Sanitary Processing Equipment, developing many of the hygienic standards and technologies that are now common place. During this period the company continued its organic growth by moving to larger premises and stabilising its operation. Utility and transfer panels were developed and introduced during this period.

In the 1990s an innovative precision engineering company, LT Engineering, previously run by Steve Overton, was amalgamated into the Suncombe organisation to incorporate their knowledge of detailed engineering and new precision techniques and to further develop and refine the Suncombe product ranges.

New technology products were developed including Biowaste Decontamination Systems, that required the full critical processing knowledge of the Suncombe organisation.

New technology products were developed including Biowaste Decontamination Systems, that required the full critical processing knowledge of the Suncombe organisation.

Cabinet Washers were also introduced to provide a method for washing process equipment. USP Water storage skids and solution preparation systems were developed.

In the 2000s a niche cleaning company, CIProcess, previously run by Dave Adams Overton, was amalgamated into the Suncombe organisation to incorporate their knowledge of niche cleaning and innovative processing and engineering systems, to further develop and refine the Suncombe product ranges.

Our Cleaning In Place, Biowaste Decontamination Systems and GMPWashers were continuously developed to incorporate changes in the Automation , control and instrumentation areas.

Our Cleaning In Place, Biowaste Decontamination Systems and GMPWashers were continuously developed to incorporate changes in the Automation , control and instrumentation areas.

Cabinet Washers were further developed into GMPWashers to provide a validated GMP method for washing process equipment.

In 2011 Suncombe celebrated their 50th Anniversary.

All product ranges were refined to provide the optimum solutions for minimising waste and energy usage. This initiative, resulted in a number of new products and technologies in Cleaning In Place, Biowaste Decontamination Systems and GMPWashers.

Today, we are still an independent company. From our beginnings in 1961 we have become a world renowned BioWaste Decontamination, Cleaning In Place, GMPWashers and Sanitary Processing Equipment supplier, with a wide portfolio of products, tremendous experience and a worldwide client base of blue chip companies.

Expertise

Our company was formed in 1961 specifically to supply a high quality range of CIP, effluent treatment and sanitary processing equipment. To continually achieve our goals, we use the most up-to-date facilities and employ the best-qualified and experienced staff.

Values

We are proud to be a Constructionline member, reflecting our dedication to ethical and sustainable business practices, as well as a sound quality management system.

Commitments

We continue to be an industry leader in innovation and proud of our recent success at the IChemE awards.

DOWNLOAD BROCHURE

Certification

- UKCA/CE Mark – we design and manufacture electro-mechanical systems and pressure systems and UKCA/CE mark in accordance with relevant directives

- We primarily design to PD5500, ASME VIII and EN 13445, with facilities for other codes. Self-certification and third-party certification are used, together with NDT Testing to code

Testing

- A Factory Acceptance Test (FAT) Protocol is compiled for all systems and is client witnessed

- The FAT incorporates full documentation checks, wet and dry system testing and is carried out to ensure our clientele that our systems are fully functional prior to despatch

- FAT report accompanies the equipment and can be used as leverage for the site based Site Acceptance Testing (SAT)

- Suncombe personnel can carry out or assist in client Qualification activities

Validation

- Our products follow the GAMP Validation Life Cycle with documentary evidence of procedures and processes during design, development, pre-construction, construction and commissioning

- Weld maps and tables linking every weld to its base materials (3.1b), the weld reference, the welder, the welder qualification and the welding machine

Documentation and data management

- Full validation documentation lifecycle. Data manual (including Instruction), Operation and Maintenance manuals, Design Drawings, Schedules and Specifications including all validation documentation

- Typical documents packages include Document Index, Quality Plan, GANTT Programme, FDS, HDS, SDS, P&ID Drawings, GA Drawings, Equipment List, Instrument List, Circuit Drawings, Software Code and Test Protocols

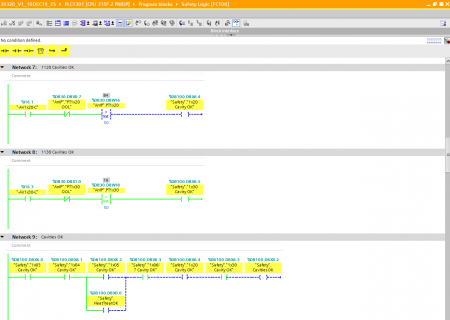

Control panels

• All design and manufacture carried out by Suncombe personnel

• 3D Control Panel Layout Design

Individually developed Electrical Diagrams

• Stainless steel enclosures

• Wired to EN60204 standards

• All cables fitted with ferrules and individually numbered

• All testing and commissioning, maintenance and servicing carried out by Suncombe personnel

Control Specification

• All specifications are developed by Suncombe personnel

• Functional Design Specification: individually compiled to confirm all operational aspects of the systems in text and flowcharts

• Hardware Design Specification: compiled to confirm hardware architecture

• Interface Specification: compiled to confirm all interfaces including hard wired, ethernet, profibus etc.

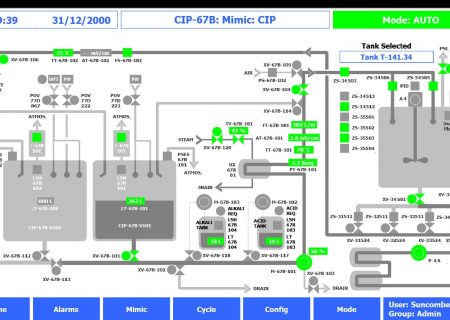

Programming

• All PLC programming, HMI development and SCADA configuration are carried out by qualified, experienced Suncombe personnel

• Programming encompasses international standard IEC 61131 for programmable logic controllers, GAMP guidelines, TickIT and IEC methodology. Compiled on current Siemens and Rockwell development platforms

• Testing in development, module testing, client source code review, change control and extensive operational testing

Risk assessment

Formal risk assessments (HAZOP, FMEA) and design reviews would be carried out as part of and throughout the detail design and construction of the system.

Project management

Quality Control

We define our approach to quality as meeting or exceeding our customer’s requirements for products and services. Our criteria include Satisfaction of Customers requirements, On-Time delivery and Continued Product Support.