BioWaste Effluent Decontamination Systems

Introduction To BioWaste Effluent Decontamination Systems

Suncombe BioWaste Effluent Decontamination Systems (EDS) decontaminate liquid hazardous infectious waste streams and liquid streams with solid suspension for: research, production, laboratory and bio-containment environments. These can also be referred to as Effluent BioWaste Treatment Plant Solutions (ETP).

Our world class systems are utilized by multiple global leading institutions. Using robust, proven design principles, our systems deal with BSL Bio Safety Level 1 to 4 waste and take into account two main areas of concern:

• Firstly, the systems effectively sterilise or inactivate any harmful pathogens in the waste stream;

• Secondly, total containment must be assured at all times.

Our capabilities allow us to design BioWaste Effluent Decontamination Systems to fit your requirements; with any number of collection and treatment vessels, built with capacities to suit the waste volume, we ensure systems are supplied with controls and interlocking functionality to ensure containment is always maintained and there is always a positive release prior to discharge of treated waste.

We offer Continuous Flow BioWaste effluent decontamination systems (EDS) and Batch BioWaste decontamination systems. Our systems are available for both thermal, thermochemical and chemical inactivation. Thermal inactivation can be performed using steam, super-heated water or an established licensed electrical heating technique which minimises time and space. Suncombe Ltd specializes in biowaste treatment solutions, offering comprehensive and innovative technologies to effectively manage and dispose of biowaste in an environmentally friendly manner. With a focus on sustainability and efficiency, Suncombe’s biowaste treatment systems ensure safe and reliable operations, helping industries and organizations meet their waste management needs effectively.

EFFLUENT DECONTAMINATION SYSTEM KEY INFORMATION

Our 60 years of designing and manufacturing EDS and ETPs has given us a clear understanding of the commercial and technical complexities often encountered during the initial stages of BioWaste system selection and development. Here at Suncombe, our vastly experienced teams of engineers are fully conversant with all aspects of biowaste effluent decontamination systems, containment facilities, and the inherent processes involved within this field.

Suncombe is a trusted authority in hazardous waste treatment, employing advanced methodologies for environmentally sound solutions. Our commitment to excellence ensures the secure and compliant management of hazardous materials. Our personnel work with experts from private companies, research institutes and governmental bodies and carry out a process of continuous professional development and training, to ensure we are always up to date with current legislation and best practices in our specific areas. The company’s systems are designed to meet the specific needs of each and every customer. Suncombe’s biowaste effluent decontamination systems are highly effective in hazardous waste treatment and removing harmful biological contaminants from wastewater.

The effluent decontamination systems are designed to be energy-efficient and environmentally friendly in order to fulfill client demands, reduce carbon emissions, and to ensure we are all making a difference for the world and future generations. Our work is conducted worldwide on some of the most prestigious institutes and applications and we would welcome the opportunity of meeting you to discuss your application and specific needs. Our engineers are highly motivated to work with our clientele to ensure the best outcome from every project that we are involved in, whilst delivering exceptional biokill systems, service, and satisfaction now and in the future.

Speak to a BioWaste specialist

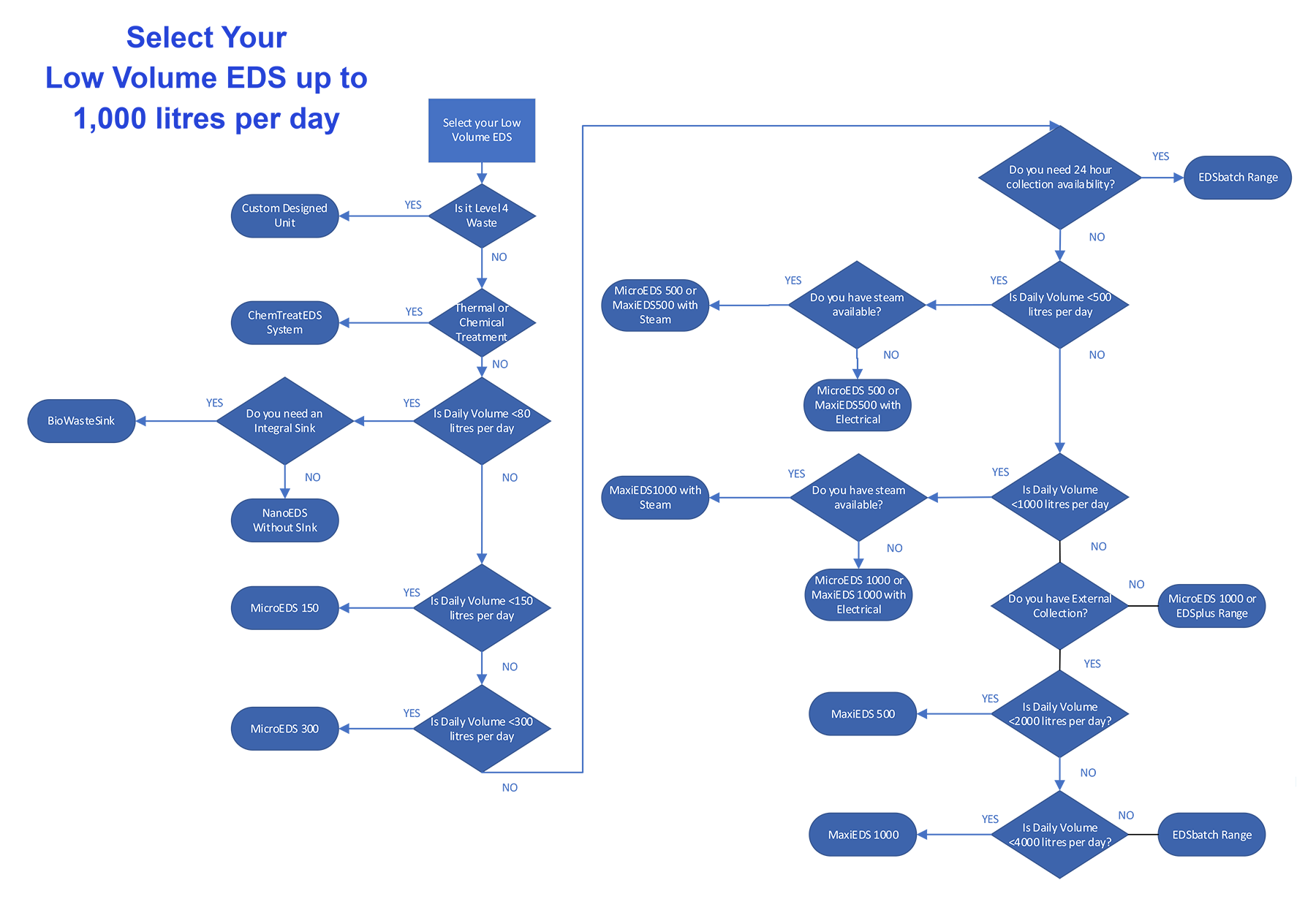

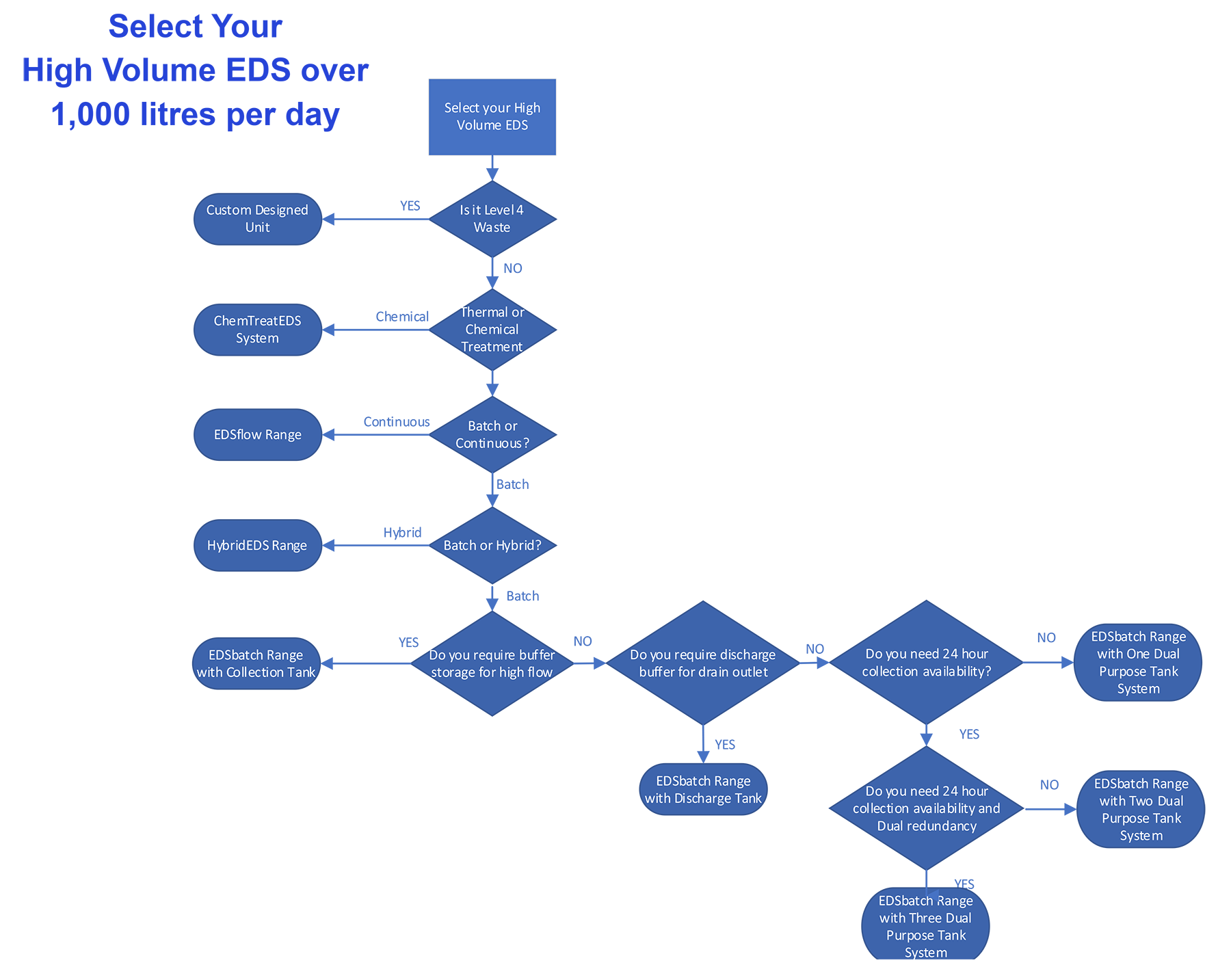

Biokill Systems Selection Guide

The Suncombe BioWaste Decontamination BioKill Systems are heavy duty validateable hazardous waste treatment systems used for the treatment of biowaste generated by research, laboratory, production and bio-containment facilities from a single laboratory room to a large multi-user facility and for production and process waste decontamination.

Our EDS systems are available in a single tank or two tank dual redundant configuration

Our systems provide multiple inactivation functions including variable temperature thermal kill, thermo-chemical kill and chemical kill.

High quality and hygienic cooling process

Using a one or two tank system can include the controlled addition of anti-foam

Using a two tank EDS+™ system allows thermal regeneration of up to 75% of energy

Using a one or two tank EDS+™ system provides the ability for self CIP

Macerator included to handle solids

If required can be installed onto the system itself/within the containment area

All our systems can be containerised if required

A single collection tank provides a buffer to collect the waste

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. To quickly generate an enquiry with us fill in the below form with as much detail as available to you, the form will auto-submit with your initial enquiry. This will enable our experts to begin assessing your system requirements and a sales representative to open a clear and concise channel of communication with you.

If you feel your line of questioning falls outside of our custom form you can contact one of our specialists by:

Phone: +44 (0) 208 804 5555

Email: salesdept@suncombe.com

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. To quickly generate an enquiry with us fill in the below form with as much detail as available to you, the form will auto-submit with your initial enquiry. This will enable our experts to begin assessing your system requirements and a sales representative to open a clear and concise channel of communication with you.

If you feel your line of questioning falls outside of our custom form you can contact one of our specialists by:

Phone: +44 (0) 208 804 5555

Email: salesdept@suncombe.com

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. Quickly fill out your information in the form below so one of our team members can help you with your specific requirements.

ASME BPE standard Pipework, fully annealed, chemistry to ASTM A-269, manufactured to ASTM A-270, and 3A Standard.

316 Stainless steel product contact parts, 304 non-contact parts, Hastelloy and Duplex Stainless.

T.I.G Welding; using argon gas purge, using a computer controlled enclosed head orbital welding plant.

PED Vessels, Complete material traceability, PD5500 compliant.

European Hygienic Engineering and Design Group (EHEDG)

Business Practices

- Cost Matrices

- Client Badging

- GAMP

- CE compliant

- Full Document Indexing

- Working to ISPE

- Industry 4.0 aware

- Complete Digital and/or physical Data Manuals

- 3D Modelling

- Corporate member of EBSA

Welding Standards

- BS EN 10204 – 3.1

- BS EN ISO 9606-1:2013

- BS EN ISO 15614-1:2004+A2:2012

Cost Matrices

Client Badging

GAMP

CE Compliant

Full Document Indexing

Working to ISPE

Industry 4.0 Ready

Data Manuals

3D Modelling

Corporate member of EBSA

Welding Standards

- BS EN 10204 – 3.1

- BS EN ISO 9606-1:2013

- BS EN ISO 15614-1:2004+A2:2012