Washing

Home > Applications > Washing

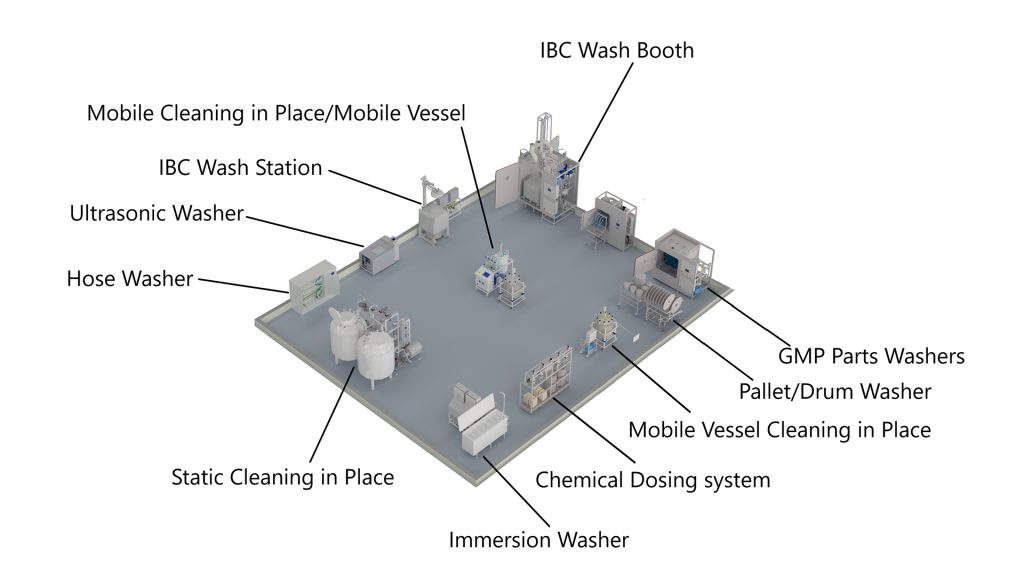

Cleaning Out Of Place (COP)

Suncombe specialise in the design and manufacture of high-performance automated COP Washers to wash contaminated IBCs (intermediate bulk containers), mobile vessels, tanks, parts, components or other items which may be moved in and out of the washing chamber.

When correctly applied automated washing provide several benefits to the user including validated repeatable, cleaning performance, improved health and safety, reduced costs for labour and utility consumption.

Washers may be designed as “total loss” systems, where the washing media is used once only before passing to drain or “recovery” systems, which recycle some of the washing media for part of the cleaning cycle.

If necessary washing cycles can conclude with the application of sanitiser.

Where contamination is not soluble in water, our systems may utilise solvents as the washing media, which requires a range of additional safety measures.

The key to successful washing is the design of automated systems which are effective at cleaning and repeatable in all possible circumstances. As automated washing reliability has improved so has its application in increasingly demanding and highly regulated industries where hygiene and avoidance of contamination is paramount, including pharmaceuticals and bio-waste.

The science of washing is based on applying the required amount of energy to the equipment to ensure that it is cleaned. The energy is primarily provided by the solution temperature (thermal energy), the use of detergent or solvent (chemical energy) and the application of kinetic energy for a defined time period. We use the ASME BPE Design Standards for GMP Washers, to ensure a repeatable, validatable wash for all of your components.

All washers are made to Suncombe’s exacting sanitary manufacturing standards.

WASHING