Transfer Panels

Home > Utility and Transfer Panels > Transfer Panels

Introduction to Transfer Panels

Process, CIP/SIP and Utility Manual Routing Panels used in Sanitary Applications

The Superior Quality cGMP Transfer Panel, providing the optimum solution to Secure Process Routing

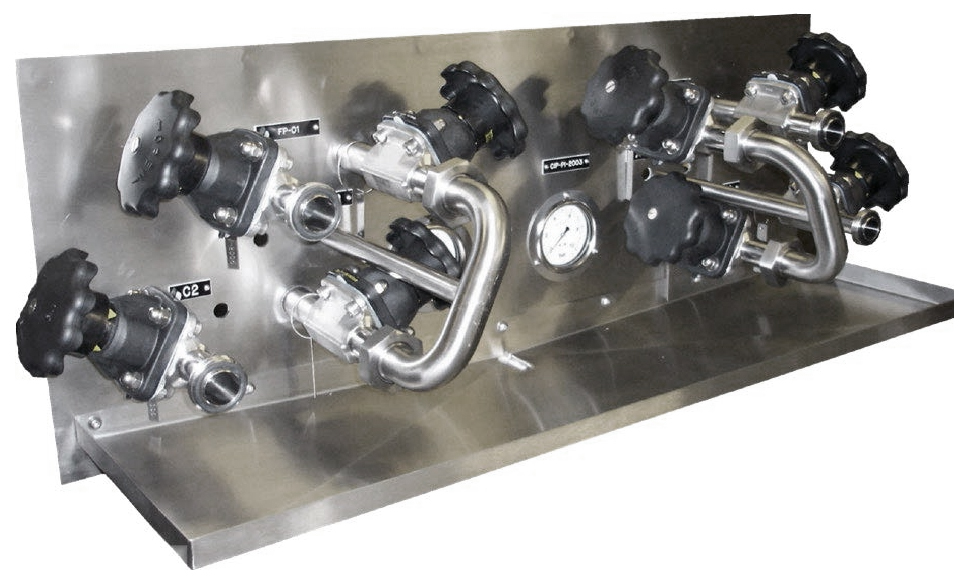

Suncombe is one of the world’s first manufacturers of panels, with transfer panels supplied since the 1960’s and Utility panels supplied since the 1970’s. Transfer Panels, also referred to as ‘U Bend Panels’, ‘3D U Bend Panels’, ‘Flowplate’s, ‘Splitter Plates’ and ‘Routing Panels’, are defined by ASME BPE as ‘a panel to which process and/or utilities are piped that mechanically precludes erroneous cross connections’.

Transfer panels use a single or a number of ‘Jumpers’ or ‘U Bends’, to manually inter-connect two or more flow paths, whilst inherently providing an ‘air break’ and physical separation to all other paths to ensure no possibility of cross contamination.

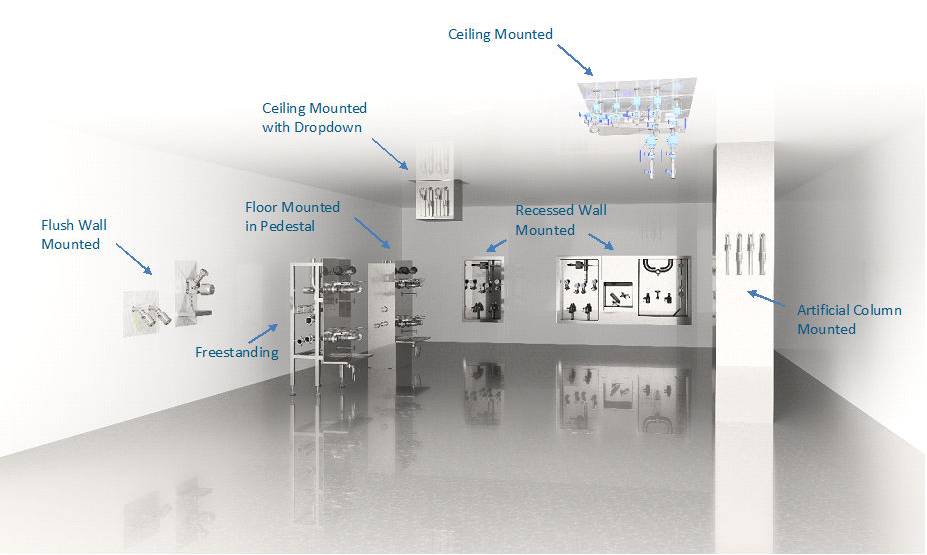

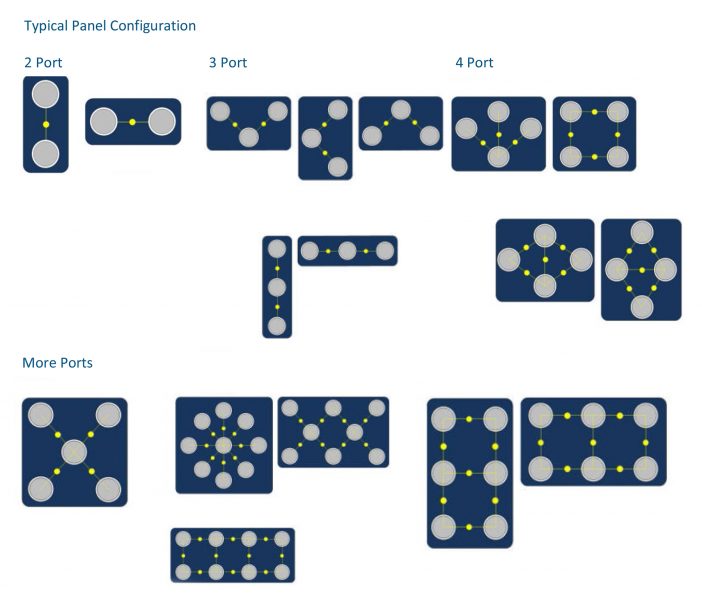

Panels are available in standard configurations with different number of ‘ports’ or ‘connections’ with a single Jumper. Custom designed panels are also available to suit your specific applications and can be developed on a flat plate (2D) or 3D matrix, and can incorporate any number and configuration of ports and any number of jumpers.

Transfer Panels Datasheet

- Polished stainless steel 316L panels

- GMP designs for free standing or through wall mounting

- Standard range and bespoke panels available

- Beveled edges for cleanability, aesthetics and health and safety

- In house development and design to suit process requirements

- ASME BPE or EHEDG sanitary construction

- Can include valves, pumps, pipework and instrumentation

- Certified surface finishes, material certificates, weld maps and tables

- Switches on port connections

- Junction Box for electrical connection

- Drip and catchment trays

- Through wall mount

- Engraved port designation and tags