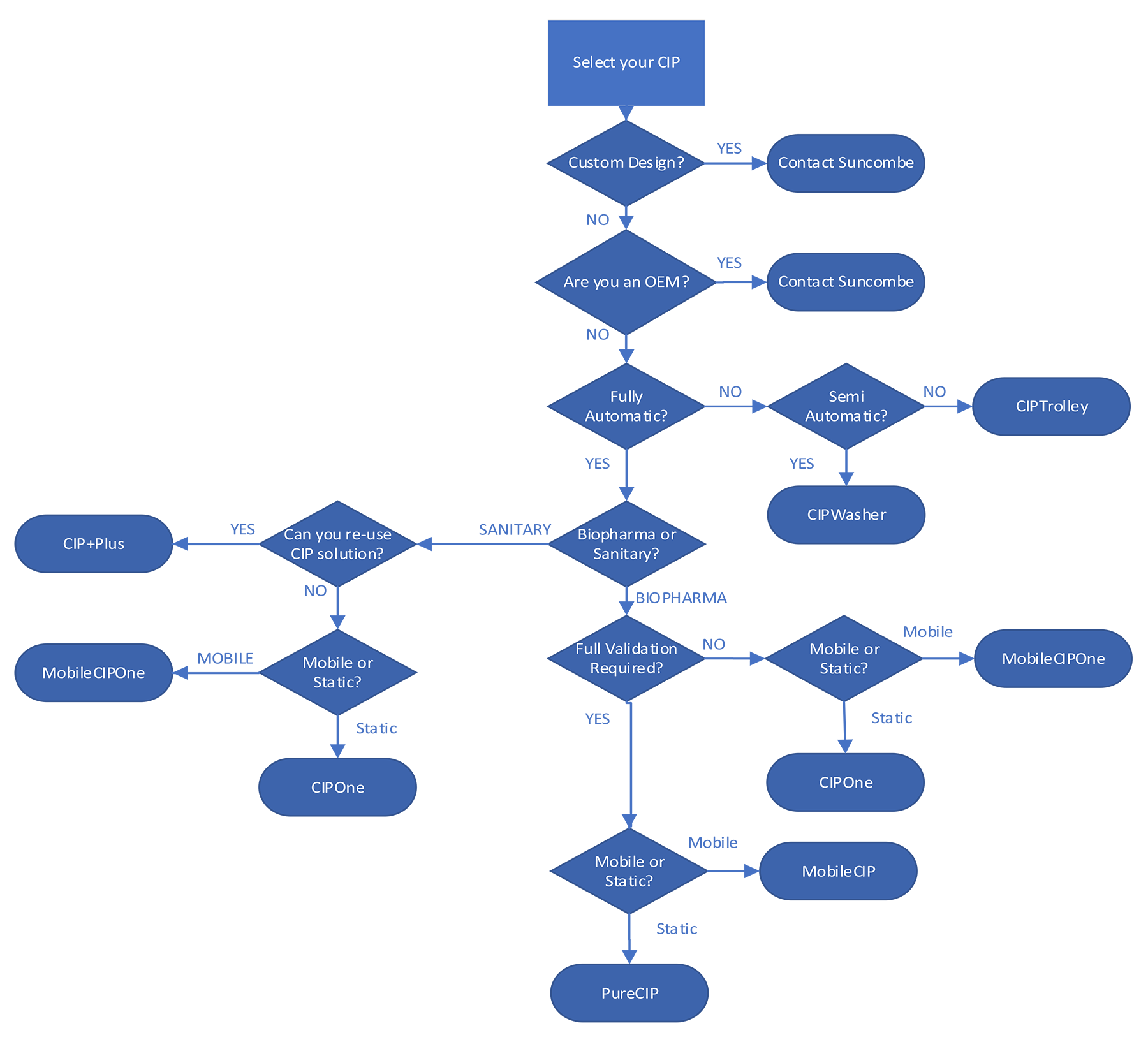

CIP Selection Guide

CIP Selection Guide

CIP (Cleaning In Place) systems are defined as equipment and techniques to allow cleaning of process equipment without dismantling, or manual cleaning with minimal operator involvement. Suncombe CIP Systems have been supplied for over 60 years and are used throughout the world in many different industries and sectors.

Speak to one of our specialists

“ Suncombe stand-out because they are specialists in the items and elements they produce. If they say they’re going to do something, they will do it… In summary, Suncombe are experts in what they do, and they’re great people to work with. ”

John Draysey, Lofthouse of Fleetwood

“ Suncombe have always been very helpful, particularly during the commissioning phase, and if we have an occasional operation problem, they are very quick to respond. I would certainly recommend them to other professionals. ”

Simon Caidan, Director of Safety, Health and Sustainability, The Francis Crick Institute

“ Suncombe's major strength is their understanding our business… They are very, very accommodating. Very knowledgeable. Always there to explain what I wasn't sure of; clarifying things. Great experience. Great people to work with. ”

Peter Timotheou, Operations Director, Tims Dairy Ltd

“ I would not hesitate to recommend or to use Suncombe again in the future. Throughout this project from design to build and test they delivered at every single milestone in terms of date and budget. Working with Dave, Steve, Mark, and the build team was a joy throughout what was a very technically difficult project to execute. For me Suncombe operate with integrity, with trust and deliver what they promise. ”

Mark Hodgson, Process Design Lead, GSK Ulvertson

“...the Suncombe engineers were incredibly highly regarded by the client ...they somehow managed to keep to the original time schedule, which was a credit to their staff and their project management skills. They are a really friendly team, and I look forward to working with them again. ”

Fearghal Downey, Hyde Engineering + Consulting

“ As well as one project for Roche in Shanghai, we’ve worked with Suncombe on projects for Novartis in Switzerland, and most recently in Spain.

The communication was good. Their documentation was brilliant. …if you asked me whether I'd work with Suncombe again – I’d say ‘definitely’ ”

Andrew Lemaire, Director, DEC Group

“ We're happy with the machine [the washer], the performance, the build quality, everything. It ticks all the boxes and it does what’s required. It’s robust and reliable, and just ticks along in the background, which is exactly what we need. ”

John Large, Technician, BCM Specials

“ I worked closely with Suncombe to develop and manufacture wash booths for several secondary pharmaceutical applications.

Manufacturing workmanship has always been superb and occasional quality issues addressed quickly and efficiently. Management commitment and support is second to none. ”

Peter Slee-Smith, Operations Director, Matcon (2001 to 2008)

“ It's definitely the most complex filtration, cleaning and sterilisation process I’ve worked on.

Their technology knowledge was very impressive and their ability to build bespoke units was very impressive too. Also, I think just the friendliness of the team really helped; it was a nice group of guys to work with. ”

James Finn, CEng MIChemE, Senior Process Engineer at Integrated Project Services Ltd

“Suncombe have been excellent. They’ve supported us with aftersales servicing and calibration needs... They’ve recently assisted us with a non-Suncombe skid, too, which has been a great help in extending the life of this asset. I always get a quick response to any requests for help. A very professional and courteous service.”

Graeme Forbes - Manufacturing Engineer - Thermo Fisher Scientific

Previous

Next