Biowaste Decontamination

Home > Applications > Hazardous Waste Treatment

As global awareness grows for the protection of the environment, so too does the demand for effective treatment or decontamination of the vast amount of bio waste and effluent created by our ever increasing society.

As global awareness grows for the protection of the environment, so too does the demand for effective treatment or decontamination of the vast amount of bio waste and effluent created by our ever increasing society.

Suncombe BioWaste Effluent Decontamination Systems (EDS) decontaminate liquid hazardous infectious waste streams for research, production, laboratory and bio-containment environments. Using robust, proven design principles, the systems deal with BSL Bio Safety Level 1 to 4 waste.

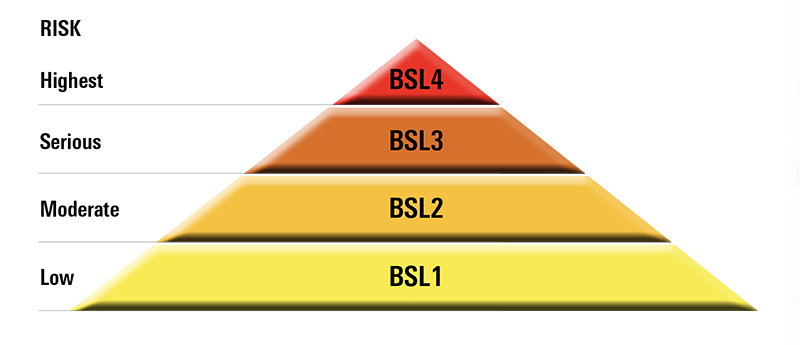

Effluent Treatment Plants (ETP) or Effluent Decontamination Systems (EDS) are classified according to Hazard Group (HG) or Biological Safety Level (BSL) or Containment Level (CL). Classification ranges from 1 (risk is relatively low and simple treatment measures are adequate), to 4 (the highest level of risk demanding the most stringent measures).

Suncombe specialise in the design and manufacture of “batch” bio waste treatment systems to the highest level, where a specific volume of liquid waste is treated according to a robust and validated process before comprehensive analysis and safe release. Suncombe Ltd specializes in hazardous waste treatment, providing innovative and reliable solutions for the safe handling & disposal of hazardous materials. With our expertise and cutting-edge technologies, we ensure efficient and environmentally-friendly processes to mitigate the risks associated with hazardous waste.

BIOWASTE DECONTAMINATION SYSTEMS

Applications include the treatment of waste generated by research, laboratory, production and biocontainment facilities.

Applications include the treatment of waste generated by research, laboratory, production and biocontainment facilities.

Depending on the level of risk, systems may incorporate dual redundancy safety measures to provide the most comprehensive protection.

Treatment involves a combination of thermal and chemical measures designed to deactivate and sterilise waste, while ensuring absolute containment and protection of the external environment. Steam, superheated water and specialised electrical heating methods may be used according to the treatment requirements.

Suncombe offers comprehensive hazardous waste treatment services to ensure the safe and environmentally friendly disposal of your hazardous materials. Our effluent decontamination systems expertly manage hazardous waste using advanced technologies, ensuring efficient and compliant handling, transportation, and disposal. Hazardous waste treatment systems can be designed for small capacity, typically associated with a single facility, up to very large capacity systems with multi-stage collection and treatment tanks.

The BioWasteBatch™ effluent treatment systems are used throughout the world for the most critical of biowaste treatment facilities and are custom designed systems which provide any number of collection and treatment tanks. Typically these separate tank systems are used for facilities which have a large throughput of waste and subsequently store the waste for gradual treatment. They are available using the traditional method of heating and cooling in the treatment vessels or our new hybrid technology of heating in the treatment vessel and cooling on the discharge. BSL4 systems incorporate multiple dual redundant safety features to ensure 100% containment both into and out of the system to guarantee that there is no possibility of untreated waste being inadvertently discharged. Our BioWasteBatch™ effluent treatment systems provide a 100% positive release of treated waste.

Effluent Decontamination System BioWasteBatch™ with Combined collection and treatment tanks Including all of the facilities of the BioWasteBatch™ effluent treatment systems with separate collection and treatment tanks, these systems are developed to utilise combined collection and treatment tanks. Minimising the inter-system transfers and transport systems this methodology lessons the reliance on pumping and transfer components. Used throughout the world in BSL4 facilities, it is primarily used for applications where facilities have typically lower peak flowrates and those when downtime periods are available in the working day. Also suitable for both traditional and our new hybrid cooling technology