EDSbatch ®

Home > BioWaste Effluent Decontamination Systems > EDSbatch ®

Introduction to EDSbatch ® Effluent Decontamination System

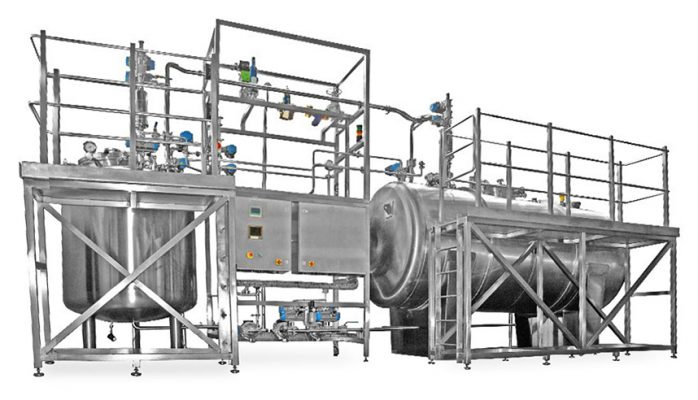

The Suncombe EDSbatch ® BioWaste Decontamination Kill Systems, previously called the EDSplus systems, are used for the treatment of effluent and waste generated by research, laboratory, production and bio-containment facilities from a single laboratory room to a large multi-user facility and for production and process waste decontamination.

Heavy duty validateable Batch BioWaste Decontamination System used for Biological Hazardous Effluent Decontamination and Growth Media Sterilisation for BSL levels 1, 2, 3 and 4, they are available in a wide range of capacities and configurations, with every system individually designed to suit each client’s specific requirements, with a dedicated Project Team, who will co-ordinate throughout the project lifecycle and agree approval prior to construction.

Using robust, proven design principles, the Suncombe EDSbatch ® BioWaste Decontamination Kill Systems uses a combination of thermal, elevated pressure processes designed to deactivate and sterilise waste, while ensuring absolute containment and protection of the external environment, ensuring that the target microbiological agents in the effluent are inactive before release.

Containerised EDSbatch ® Systems

Want to know more about our systems? Go to Suncombe Biokill System page.

EDSbatch ® Datasheet

Containment Level: BSL1, BSL2, BSL3, BSL4

Treatment Vessels: Any Number

Collection Vessels: Any Number

System Capacity: Up to 45,000L per day

Treatment Temperatures: Variable up to 136°C and preset to 121°C for up to 30 minutes

System Cooling: 43C with cooling utility

Material: 316 Stainless steel, duplex or Hastelloy

Operating Voltage: 400VAC

Automation: BioSuite Level 2000 standalone control system with touch panel display