Utility and Transfer Panels

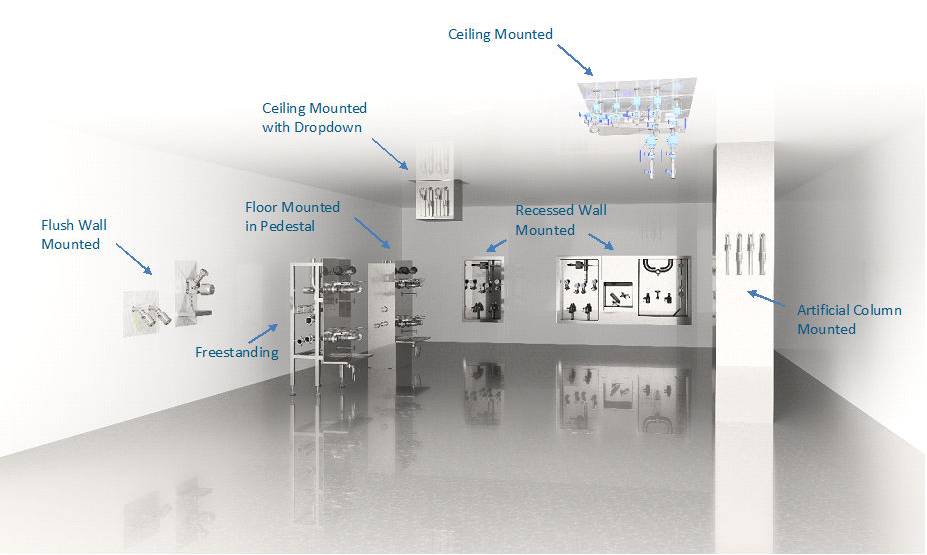

As one of the world’s first manufacturers of transfer panels, Suncombe Transfer Panels have been produced by Suncombe for over 50 years. The panels are used for service entry, utility entry, CIP and SIP routing and also for utility piping and control outside of the clean area.

This principle removes the equipment and instruments from the production areas by locating them in service areas, providing additional production area space and allowing maintenance outside of production areas.

Speak to one of our specialists

Our Transfer Panels have radius edges and no exposed threads

180° Swing bends

Primarily built to ASME BPE SF1 and SF4 for hygienic services, suitable materials and piping standards are used for other utilities

Wetted parts surface descaled and bead removed, non wetted parts satin polished

Glycol, oxygen, WFI, PW

Z-clips, Switches for swing bend position, Thru-wall mounting versions

ATEX versions are available for solvent use and/or aqueous use in zoned areas.

Standard configurations and custom designed, the transfer panels are manufactured from 316 stainless steel

Dry break QC, Process fitting Tri-clamps and Weld ends

Sinks and Tundishes allow for free draining

Transfer bosses, pipe spec changes and surface finishes

Integration with Suncombe CIP and process systems

Engravings/Brandings of your logo are optional if required

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. To quickly generate an enquiry with us fill in the below form with as much detail as available to you, the form will auto-submit with your initial enquiry. This will enable our experts to begin assessing your system requirements and a sales representative to open a clear and concise channel of communication with you.

If you feel your line of questioning falls outside of our custom form you can contact one of our specialists by:

Phone: +44 (0) 208 804 5555

Email: salesdept@suncombe.com

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. To quickly generate an enquiry with us fill in the below form with as much detail as available to you, the form will auto-submit with your initial enquiry. This will enable our experts to begin assessing your system requirements and a sales representative to open a clear and concise channel of communication with you.

If you feel your line of questioning falls outside of our custom form you can contact one of our specialists by:

Phone: +44 (0) 208 804 5555

Email: salesdept@suncombe.com

We are able to accommodate multiple user requirements, and are experienced in designing and manufacturing systems to various specification variables. Quickly fill out your information in the form below so one of our team members can help you with your specific requirements.

ASME BPE standard Pipework, fully annealed, chemistry to ASTM A-269, manufactured to ASTM A-270, and 3A Standard.

316 Stainless steel product contact parts, 304 non-contact parts, Hastelloy and Duplex Stainless.

T.I.G Welding; using argon gas purge, using a computer controlled enclosed head orbital welding plant.

PED Vessels, Complete material traceability, PD5500 compliant.

European Hygienic Engineering and Design Group (EHEDG)

Cost Matrices

Client Badging

GAMP

CE Compliant

Full Document Indexing

Working to ISPE

Industry 4.0 Ready

Data Manuals

3D Modelling

Corporate member of EBSA

Welding Standards

- BS EN 10204 – 3.1

- BS EN ISO 9606-1:2013

- BS EN ISO 15614-1:2004+A2:2012

Andrew Lemaire

Director, DEC Group