Processing Skids

Home > Applications > Processing Skids

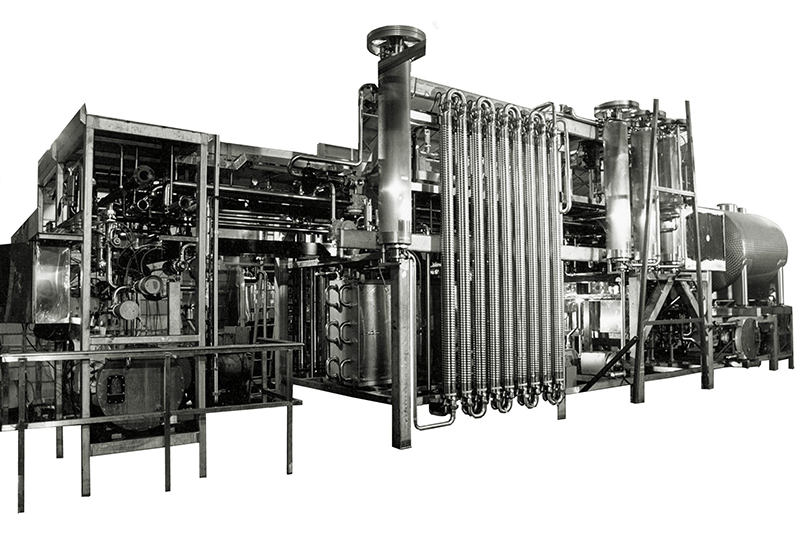

Suncombe offers a design and build service for the production of customised skid mounted liquid processing modules.

Applications include solution preparation, buffer and media preparation, final formulation and fill, utility preparation, temperature control systems, powder incorporation, pH neutralisation, chemical dosing and many more.

Skid mounted or modular systems offer tremendous advantages in project planning and risk management as they are built and fully tested off-site in parallel to facility construction work, allowing minimal time and risk in the installation and validation phases.

All systems include comprehensive automation to ensure validated repeatable, process performance, improved health and safety, reduced costs for labour and utility consumption.

PROCESSING SKIDS

Testimonials

Processing skids and systems are pre-fabricated, skid-mounted modules that integrate all equipment (piping, vessels, instrumentation, controls) to execute a defined liquid process, which is built off-site and delivered ready for installation.

Typical applications include solution preparation, buffer/media prep, final formulation & fill, utility preparation, temperature control systems (like HTST), powder incorporation, pH neutralisation, chemical dosing and more.

The three core benefits are:

- Parallel build: the skid can be constructed and tested off-site while the facility is built.

- Reduced installation and commissioning time.

- Factory acceptance testing (FAT) under controlled conditions ensures higher quality.

Suncombe’s processing skids are constructed using sanitary 316L stainless steel (with 304 for non-contact), ASME BPE piping, no dead-legs, a fully drainable design, orbital welding, and weld traceability.

Our skids include recipe-based control systems, PLC/HMI interfaces, audit trails and batch reports (21 CFR11 compliance), remote access interfaces and integration into plant automation networks.