The Francis Crick Institute BioWaste Treatment Facility

The Facility

The Francis Crick Institute is an ambitious project to create a world-leading biomedical research institute at the heart of London, dedicated to understanding the fundamental biology underlying human health and illness. The Francis Crick Institute was founded by six of the UK’s most successful scientific and academic organisations – the Medical Research Council (MRC), Cancer Research UK (CRUK), the Wellcome Trust, UCL (University College London), Imperial College London and King’s College London. The organisations in the consortium have invested a total of around £650 million to establish the institute and to ensure that it is resourced to make a major impact.

The Project

To provide a state-of-the-art effluent treatment facility for Containment Level 4 wastes for the new research laboratories at The Francis Crick Institute. A large and highly sophisticated project with an extremely high environmental performance criteria including reliability and redundancy.

Courtesy of The Francis Crick Institute

Our Approach

We started by reviewing the initial building specifications and worked with the client to develop 3D models of the proposed ETP envelope. The envelope was dimensioned and modelled to allow ingress and emergency access for the Effluent Treatment equipment. Following preliminary design, we held and attended design evaluation meetings, HAZOPs and risk assessment, to jointly develop the optimum methodology for guaranteed effluent treatment at a high containment level. We identified and specified all the performance testing needed to carry out in order to provide test results and demonstrations and developed the planning of the testing and commissioning of the final system early in the project programme. We identified all of the critical outcomes and the requirements of the statutory authorities and using these we developed the designs. We worked in close cooperation with the client and long term Suncombe engineers who have been working on biowaste effluent treatment and critical decontamination and sterilisation system throughout our companies 50+ years of operation. Throughout the detailed development, design and construction process, we worked with client and contractors personnel to ensure that the system would successful integrate into the building structure and with the other disciplines involved. We provided mock-ups, prototypes and bench scale testing to prove the development designs.

System Installed On Site

System 3D Model

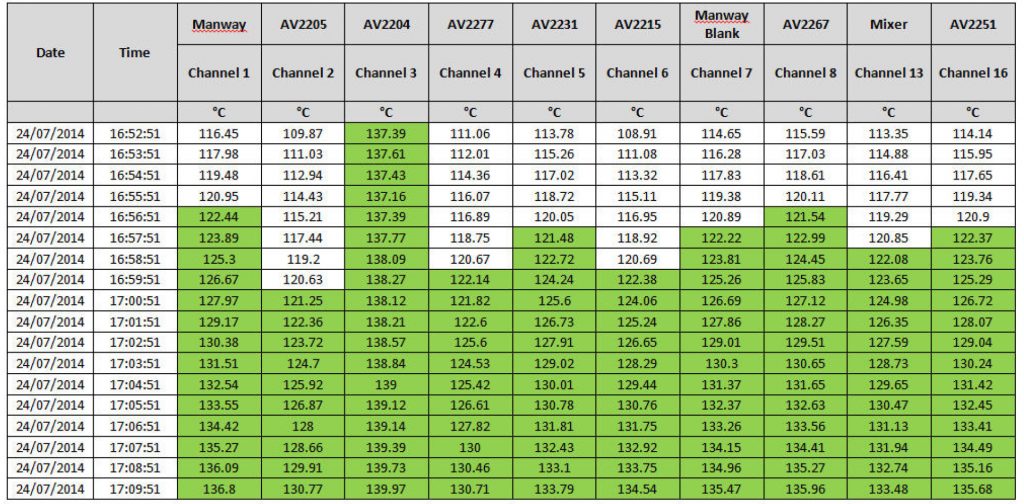

Factory Acceptance Testing

The construction programme was finished on schedule and there followed a four week Factory Acceptance Testing, carried out to pre-approved testing protocols. System documentation and certifications were reviewed, as well as full testing including automation and dry run simulations followed with wet testing and system thermal inactivation cycles. These extensive pre-delivery tests were carried out to ensure that on delivery to site the system was pre-tested ensuring that reconnection and preparedness for operation was straight forward. Following delivery and installation, the testing regime continued with the next stage of Site Acceptance Testing, once again against pre-approved protocols. Tests were carried out to prove that the installed system maintained the operation of the Factory.

System Thermal Mapping Chart

Clients Comments

Simon Caidan, Director of Safety, Health and Sustainability for The Francis Crick Institute said, “The Francis Crick Institute, as one of the world’s leading medical research institutes, needs to be able to rely on its world class facilities and it is vitally important that the effluent treatment facilities are able to cope and remain fully compliant with High Containment requirements. The Suncombe system met our challenging specifications and is working well,” he added.

Suncombe Comments

Steve Overton, technical director at Suncombe, commented, “We were delighted to be part of this project which is a world-leading medical research centre. The project provided great challenges for our team and I am proud to say that these challenges were met and exceeded. As British manufacturers ourselves I am pleased we could support this worldleading project.”

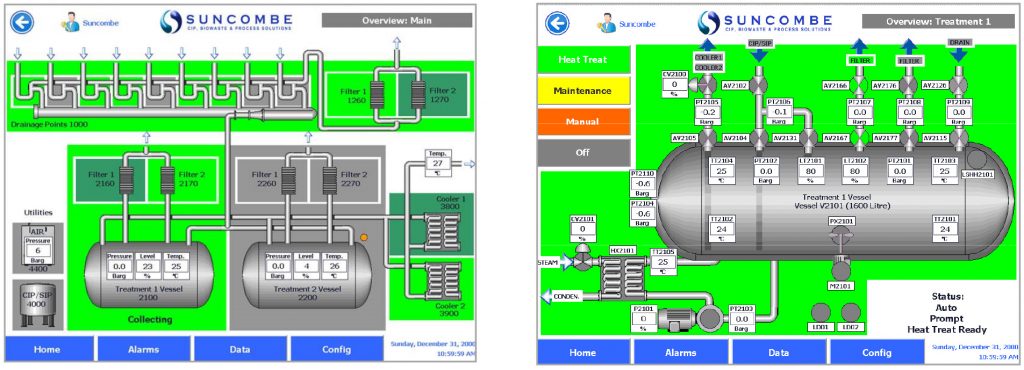

Control System Screens

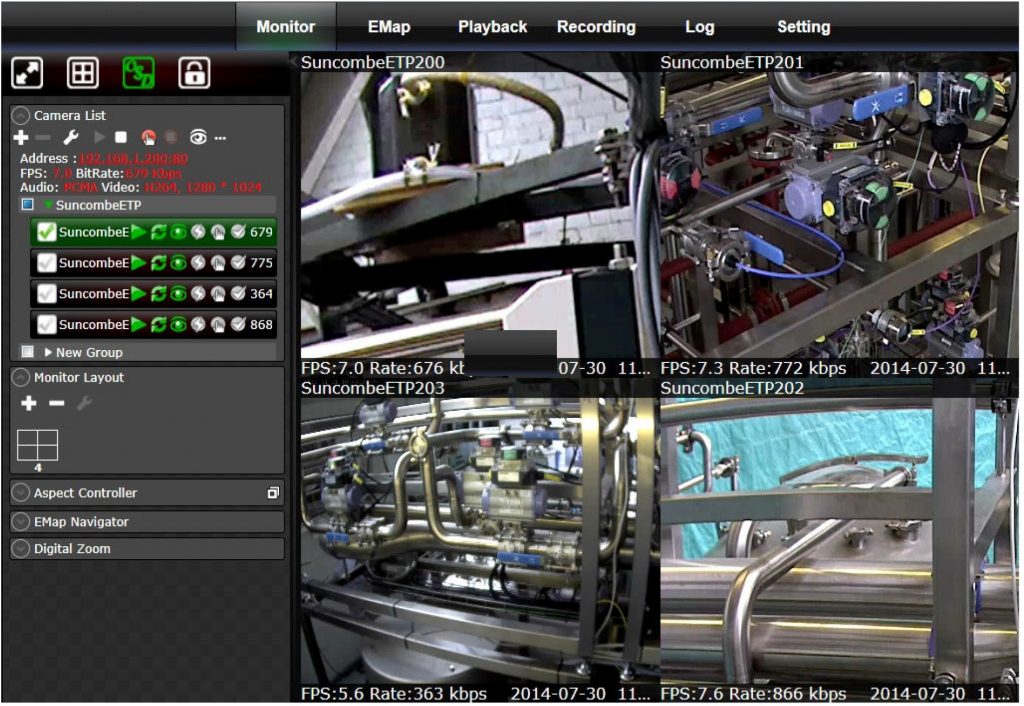

System CCTV Cameras