Pirbright Institute Highest Level Effluent Treatment

The facility

The Pirbright Institute is a world leading centre of excellence in research and surveillance of virus diseases of farm animals and viruses that spread from animals to humans. Working to enhance capability to contain, control and eliminate these economically and medically important diseases, the Institute’s highly innovative fundamental and applied bioscience contributes to global food security and health, improving quality of life for animals and people.

Courtesy of The Pirbright Institute

Courtesy of The Pirbright Institute

The project

The construction and commissioning of a new 11,065m² research laboratory that will further develop The Pirbright Institute as a world-class centre of excellence for research into viral diseases of livestock. The project, designed and constructed by Shepherd Construction, included a new main laboratory building, a new gatehouse, energy centre and infrastructure. Within the main building is a central hub with north, east and west wings which accommodate the highest level bio containment (level 4) laboratories. One of the main drivers in the building’s design was the requirement to achieve air tightness levels that are up to 1100 times higher than normal building regulations requirements.

Courtesy of The Pirbright Institute

Courtesy of The Pirbright Institute

The challenge

To provide a state-of-the-art effluent treatment facility for Containment Level 4 wastes for the new research laboratories at The Pirbright Institute. A large and highly sophisticated project with an extremely high environmental performance criteria including reliability and redundancy.

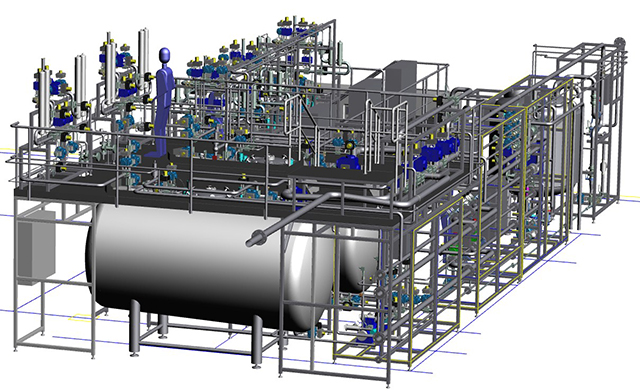

The Pirbright Institute ETP 3D Model

The Pirbright Institute ETP 3D Model

Our approach

We started by reviewing the initial building specifications and worked with the client to develop 3D models of the proposed ETP envelope. The envelope was dimensioned and modelled to allow ingress and emergency access for the Effluent Treatment equipment. Following preliminary design, we held and attended design evaluation meetings, HAZOPs and risk assessment, to jointly develop the optimum methodology for guaranteed effluent treatment at the containment level 4. We identified and specified all the performance testing needed to carry out in order to provide test results and demonstrations and developed the planning of the testing and commissioning of the final system early in the project programme. We identified all of the critical outcomes and the requirements of the statutory authorities and using these we developed the designs. We worked in close co-operation with the client and long term Suncombe engineers who have been working on biowaste effluent treatment and critical decontamination and sterilisation system throughout our company’s 50+ years of operation.

Throughout the detailed design and construction process, we worked with client and contractors personnel to ensure that the system would successful integrate into the building structure and with the other disciplines involved. The construction programme was finished on schedule and there followed a four week Factory Acceptance Testing, carried out to pre-approved testing protocols. System documentation and certifications were reviewed, as well as full testing including automation and dry run simulations followed with wet testing and system thermal inactivation cycles. These extensive pre-delivery tests were carried out to ensure that on delivery to site the system was pre-tested ensuring that reconnection and preparedness for operation was straightforward.

Following delivery and installation, the testing regime continued with the next stage of Site Acceptance Testing, once again against pre-approved protocols. Tests were carried out to prove that the installed system maintained the operation of the Factory Accepted system and continued on to challenge testing and bio-deactivation testing.

Our engineering

- 50+ years of Engineering Excellence

- Equipment manufactured in Europe

- Designed and manufactured to CE, cGMP, PED, ASME, GAMP, ATEX.

- In-house personnel for all disciplines

- Single point of contact for all aspects of a Project

- Full documentation and validation service

- Factory testing of all equipment

The Pirbright Institute ETP In Construction

The Pirbright Institute ETP In Construction

The Pirbright Institute ETP During Installation

The Pirbright Institute ETP During Installation