Chemical Distribution Schemes

Home > Chemical Distribution Schemes

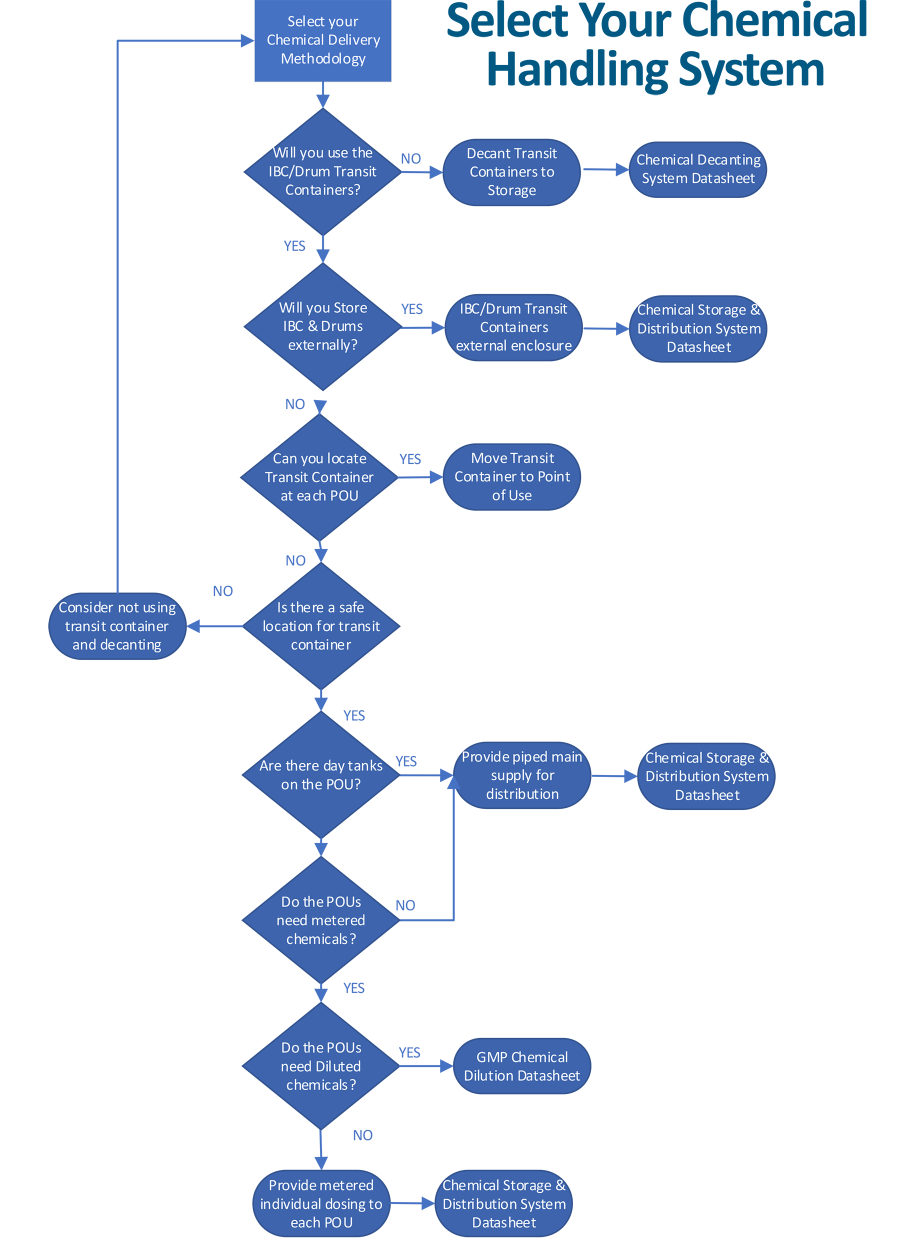

Introduction to Chemical Distribution Schemes

Suncombe Chemical Distribution Schemes are a robust range of heavy duty schemes for internal and external storage and distribution of liquid chemicals. Primarily used in the pharmaceutical, biotech, food, beverage, healthcare and other critical sectors, they encompass the high quality of design, manufacture and documentation required in these sectors.

Description

Individually developed for clients specific requirements, Suncombe Chemical Distribution Schemes provide a robust, reliable, repeatable method of storage and distribution of liquids. They incorporate internal and/or external enclosures for containing liquid IBCs and drums, pipework, pumps, valves, instrumentation and an in-built control system.

Features

- Developed and manufactured in the United Kingdom

- Safe storage for chemicals in internal or external locations

- Self bunded systems with combined or split bunds

- Local day tanks, pumping stations and manual filling stations

- External versions weatherproofed, heated and ventilated

- Safety showers and eyebaths

- Available for many liquid solutions and chemical compounds

- High quality stainless, duplex, PE and compatible material schemes

- 316 stainless steel pipework as standard

- Duplex steel or plastic pipework for chemical compatibility

- Safety Interlocks to SIL2

- Automatic or manual changeover of twin IBCs or drums

- Pressure relief and safety devices

- Risk assessment, method statements, operating instructions and full documentation

- 2D drawings and 3D models supplied

- Factory Acceptance Testing Included

Chemical Distribution Datasheet

Automation Philosophy: Manual, Semi-automatic, automatic

Number of IBCs/Drums in Scheme: 1 – 10

Number of IBCs/Drums in Enclosure: 1 – 4

Operating Voltage: 230VAC or 400VAC (24VDC control) – international voltage options

Automation: Suite Levels 1000 to 4000 – option for DCS/remote control

Reporting: Optional printed 21CFR11 electronic records and batch reports.

Speak to a specialist

Suncombe Chemical Distribution Schemes are systems engineered for the safe storage, handling, and distribution of liquid chemicals in controlled environments. They contain storage enclosures (internal or external), secondary containment (bunds), pipework, pumps, valves, instrumentation and control systems.

Our chemical distribution systems are tailored for critical sectors such as pharmaceutical, biotechnology, food & beverage, healthcare and other high-purity/manual hazard environments where chemical distribution must meet rigorous standards.

Chemical distribution systems are available for both high-volume bulk storage tanks (external or internal) and for distribution from transit containers like IBCs or drums.

Depending on chemical compatibility, chemical distribution systems have 316L stainless steel pipework, minimal dead-legs, a fully drainable design, traceable welds/materials, and corrosion-resistant thermoplastics or duplex alloys.

Yes, external versions are weather-proofed, heated, ventilated and include self-bunded cabinets for IBCs or drums located outdoors.

Suncombe’s chemical distribution systems are designed for longevity (25+ year life), and emphasise sustainable design to reduce waste, energy-efficient components, recyclable materials, and minimal site infrastructure thanks to pre-assembly.